G4-68, Y4-68 boiler centrifugal fan

1, use

G4-68, Y4-68 type centrifugal pass, induced draft fan for thermal power plant in the 230t / h following steam boiler pass, cited wind matching. G4-68 can also be used for mine ventilation and general ventilation when there are no other special requirements.

The medium for the ventilator is air. The maximum temperature shall not exceed 80 ℃, induced by the fan for the flue gas, the maximum temperature shall not exceed 250 ℃. In the fan before, must be installed dust removal efficiency of not less than 85% of the dust removal device, reducing the smoke into the fan dust content, in order to improve the service life of the fan.

2, form

(1) ventilator and induced draft fan are made of single inhalation, each with No.8-16 a total of 7 machine number.

(2) Each fan can be made in the right rotation or left rotation in two forms, from the motor side of the fan, the impeller clockwise rotation called the right rotating fan, with "right", the wheel by counterclockwise rotation called L- The fan is indicated by "left".

(3) The outlet position of the fan is expressed by the angle of the outlet of the cabinet. The "right" and "left" fans can be made into 0 °, 45 °, 90 °, 135 °, 180 ° and 225 °.

(4) fan drive mode for the D-type, motor and fan connection using flexible coupling direct drive.

(5) Product name for example: GY4-68No.8D right 90, where G, Y, respectively, said boiler fan and boiler fan.

3, structural characteristics

The blades are mainly composed of impeller, housing, air inlet, regulating door and rotating part.

(1) Impeller: 12 rear wing wings welded to the arc of the wheel cover and flat-shaped discs in the middle, due to the use of wing-shaped blades to ensure that the fan of high efficiency, low noise, high strength. Impeller by static, dynamic balance correction running smoothly. The same machine through the same, the same fan impeller structure.

(2) Case: The chassis is made of ordinary steel plate welded by the scroll body. The fan of the chassis made of the overall structure.

For the induced draft fan, in the scroll plate on a clean door, while appropriate thickening to prevent the wear and tear to extend its service life.

(3) Air inlet: Integral structure for the convergence of the streamline, with the bolt on the inlet side of the housing.

(4) Regulating door: The device used to adjust the flow rate of the fan. No.8-12.5 consists of 11 petal-type blades. No.14-16 is composed of 13 petal-type blades, which are axially mounted in front of the inlet. As a result of the external transmission structure, flexible and convenient rotation. Adjust the range from 90 ° (fully closed) to 0 ° (fully open). Adjust the door of the handle position, from the direction of the air inlet, on the right side. For the right-hand fan, pull the handle from the bottom up by the whole closed to fully open direction; for the left whirlwind fan, pull the handle from the top down is fully closed to fully open direction.

In order to make the adjustment of the various parts of the normal work, must be very good lubrication. Adjust the door of the fan, the use of calcium-based grease lubrication. On the induced draft fan, due to higher gas temperature, grease using molybdenum disulfide high temperature (260 ℃) grease, high temperature operation to ensure lubrication.

(5) drive group: transmission are D-type. By the spindle, bearing box, coupling and other components. The spindle is made of high quality steel. The use of rolling bearing water cooling the overall bearing box. Therefore, the need to install water pipes, water consumption varies depending on the ambient temperature, generally considered 0.5-1m3 / h. The thermostat and oil level indicator are fitted on the bearing housing. Lubricating oil with full loss system oil L-AN46. Add the oil level to the oil level mark.

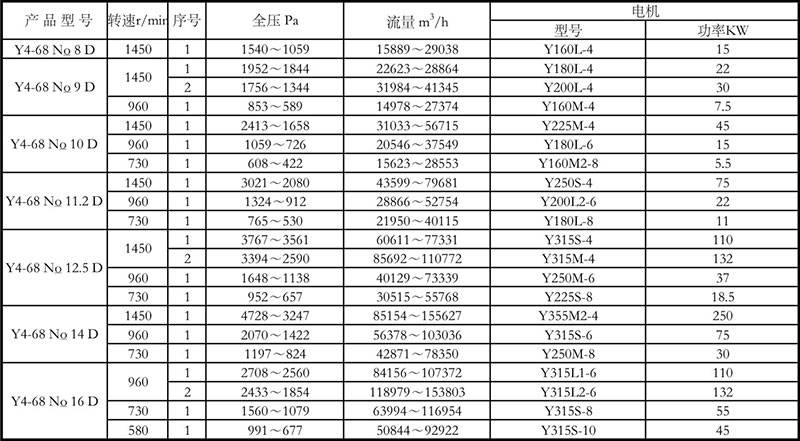

Performance and Options Table

G4-68, Y4-68 type centrifugal pass, induced draft fan for thermal power plant in the 230t / h following steam boiler pass, cited wind matching. G4-68 can also be used for mine ventilation and general ventilation when there are no other special requirements.

The medium for the ventilator is air. The maximum temperature shall not exceed 80 ℃, induced by the fan for the flue gas, the maximum temperature shall not exceed 250 ℃. In the fan before, must be installed dust removal efficiency of not less than 85% of the dust removal device, reducing the smoke into the fan dust content, in order to improve the service life of the fan.

2, form

(1) ventilator and induced draft fan are made of single inhalation, each with No.8-16 a total of 7 machine number.

(2) Each fan can be made in the right rotation or left rotation in two forms, from the motor side of the fan, the impeller clockwise rotation called the right rotating fan, with "right", the wheel by counterclockwise rotation called L- The fan is indicated by "left".

(3) The outlet position of the fan is expressed by the angle of the outlet of the cabinet. The "right" and "left" fans can be made into 0 °, 45 °, 90 °, 135 °, 180 ° and 225 °.

(4) fan drive mode for the D-type, motor and fan connection using flexible coupling direct drive.

(5) Product name for example: GY4-68No.8D right 90, where G, Y, respectively, said boiler fan and boiler fan.

3, structural characteristics

The blades are mainly composed of impeller, housing, air inlet, regulating door and rotating part.

(1) Impeller: 12 rear wing wings welded to the arc of the wheel cover and flat-shaped discs in the middle, due to the use of wing-shaped blades to ensure that the fan of high efficiency, low noise, high strength. Impeller by static, dynamic balance correction running smoothly. The same machine through the same, the same fan impeller structure.

(2) Case: The chassis is made of ordinary steel plate welded by the scroll body. The fan of the chassis made of the overall structure.

For the induced draft fan, in the scroll plate on a clean door, while appropriate thickening to prevent the wear and tear to extend its service life.

(3) Air inlet: Integral structure for the convergence of the streamline, with the bolt on the inlet side of the housing.

(4) Regulating door: The device used to adjust the flow rate of the fan. No.8-12.5 consists of 11 petal-type blades. No.14-16 is composed of 13 petal-type blades, which are axially mounted in front of the inlet. As a result of the external transmission structure, flexible and convenient rotation. Adjust the range from 90 ° (fully closed) to 0 ° (fully open). Adjust the door of the handle position, from the direction of the air inlet, on the right side. For the right-hand fan, pull the handle from the bottom up by the whole closed to fully open direction; for the left whirlwind fan, pull the handle from the top down is fully closed to fully open direction.

In order to make the adjustment of the various parts of the normal work, must be very good lubrication. Adjust the door of the fan, the use of calcium-based grease lubrication. On the induced draft fan, due to higher gas temperature, grease using molybdenum disulfide high temperature (260 ℃) grease, high temperature operation to ensure lubrication.

(5) drive group: transmission are D-type. By the spindle, bearing box, coupling and other components. The spindle is made of high quality steel. The use of rolling bearing water cooling the overall bearing box. Therefore, the need to install water pipes, water consumption varies depending on the ambient temperature, generally considered 0.5-1m3 / h. The thermostat and oil level indicator are fitted on the bearing housing. Lubricating oil with full loss system oil L-AN46. Add the oil level to the oil level mark.

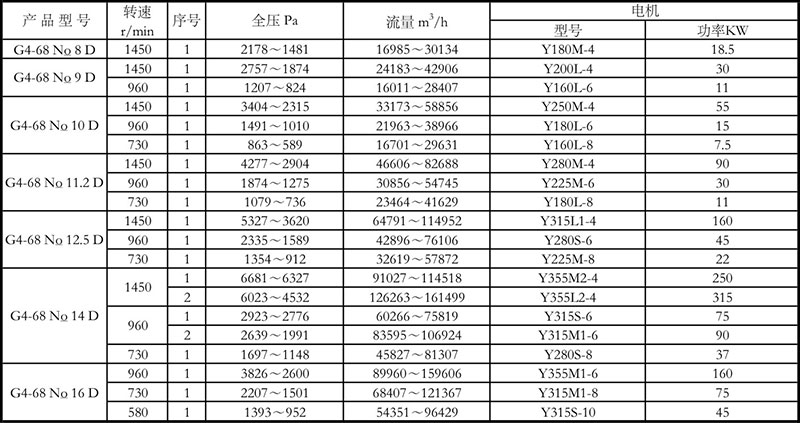

Performance and Options Table

Performance and Selection Table