T4-72 Centrifugal fan

T4-72 centrifugal fan

Machine number: 3 # ~ 20 #

Air volume: 794 ~ 408000m3 / h

Total pressure: 179 ~ 3150pa

Application: As a general factory and large buildings indoor ventilation, can be used as input gas, can also be used as output gas. Transport medium: air and other non-spontaneous, harmless to the human body, the steel material is not corrosive gas, the gas is not allowed to sticky material, contains dust and hard particles not more than 150 mg / cubic meter.

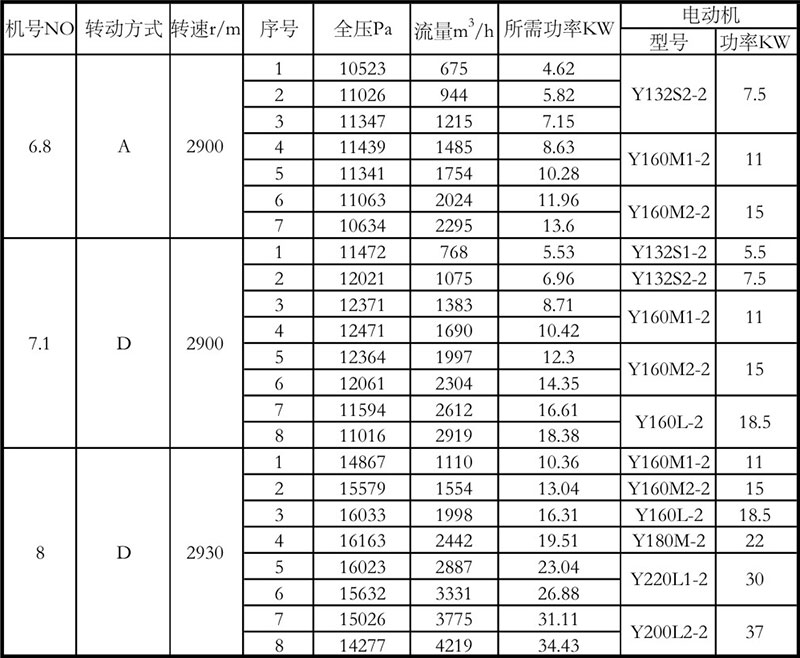

T4-72 performance and optional table

Machine number: 3 # ~ 20 #

Air volume: 794 ~ 408000m3 / h

Total pressure: 179 ~ 3150pa

Application: As a general factory and large buildings indoor ventilation, can be used as input gas, can also be used as output gas. Transport medium: air and other non-spontaneous, harmless to the human body, the steel material is not corrosive gas, the gas is not allowed to sticky material, contains dust and hard particles not more than 150 mg / cubic meter.

T4-72 performance and optional table

6-30 centrifugal fan

6-30 centrifugal fan discharge medium for the air and non-corrosive, unnatural, non-viscous material of the gas, the temperature does not exceed 80 ℃, the fan has a larger pressure, less flow characteristics, suitable for Food, cotton and other processing of wind transmission.

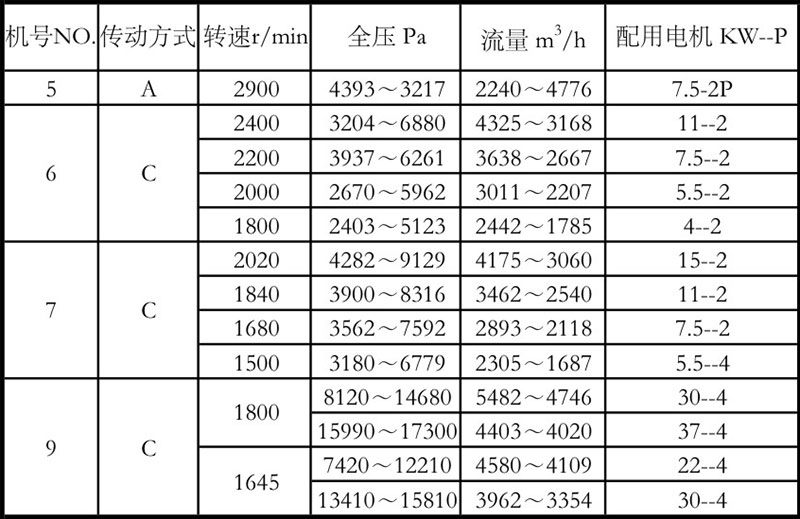

6-30 grain, powder delivery centrifugal fan performance parameters table

6-30 centrifugal fan discharge medium for the air and non-corrosive, unnatural, non-viscous material of the gas, the temperature does not exceed 80 ℃, the fan has a larger pressure, less flow characteristics, suitable for Food, cotton and other processing of wind transmission.

6-30 grain, powder delivery centrifugal fan performance parameters table

8-09,9-12 type centrifugal fan

1, Uses: 8-09,9-12 type of iron furnace dedicated high-pressure centrifugal fan, suitable for 1 L / h, 2L / h, 3L / h, 7L / h melting rate of iron furnace blast performance requirements. The fan can also be used as a variety of furnace forging furnace furnace blast, but also for conveying air and non-corrosive, non-spontaneous combustion, does not contain viscous material gas. The temperature of the input medium does not exceed 80 ℃, the media contains dust and hard fine particles not more than 150mg / m3.

2, the form: 8-09 fan for a single inhalation, machine number has No.6.8A, 7.1D, 8D, 8.5D, 9D a total of five.

9-12 fan for a single inhalation, machine number No6.8A, 7.1 A, 7.7A, 8D, 9D a total of five machine number.

8-09,9-12 fan can be made clockwise or counterclockwise rotation in two forms. From the motor side of the face, such as the impeller clockwise rotation, said clockwise rotation of the fan to "Shun" said, according to counterclockwise rotation, said counterclockwise rotation fan to "inverse" said.

The outlet position of the fan is expressed as the angle of the outlet of the enclosure. The "Shun" and "reverse" fans can be made into 0 °, 90 ° and 180 ° angles.

3, structural features: 8-09,9-12 fan by the impeller, chassis, air inlet, rotation group, seals, base and other components, for the 8-09 machine with local assembly mechanism, the other machine using the overall body The

① Impeller leaves are designed according to the new efficient forward fan theory. Impeller after forming by static, dynamic balance correction, so smooth and reliable operation.

② the chassis with ordinary steel welded into a scroll shell as a whole.

③ the air inlet made of convergent streamline of the overall structure, with bolts and front cover group fixed.

④ rotating group by the spindle, bearing box, coupling and other components, the spindle made of high quality steel. For the 8-09 type No.71 D, No. 8D using rolling bearing lubrication grease lubrication, for the 8-D9 type No. 5.8, using rolling bearing lubricating oil lubrication.

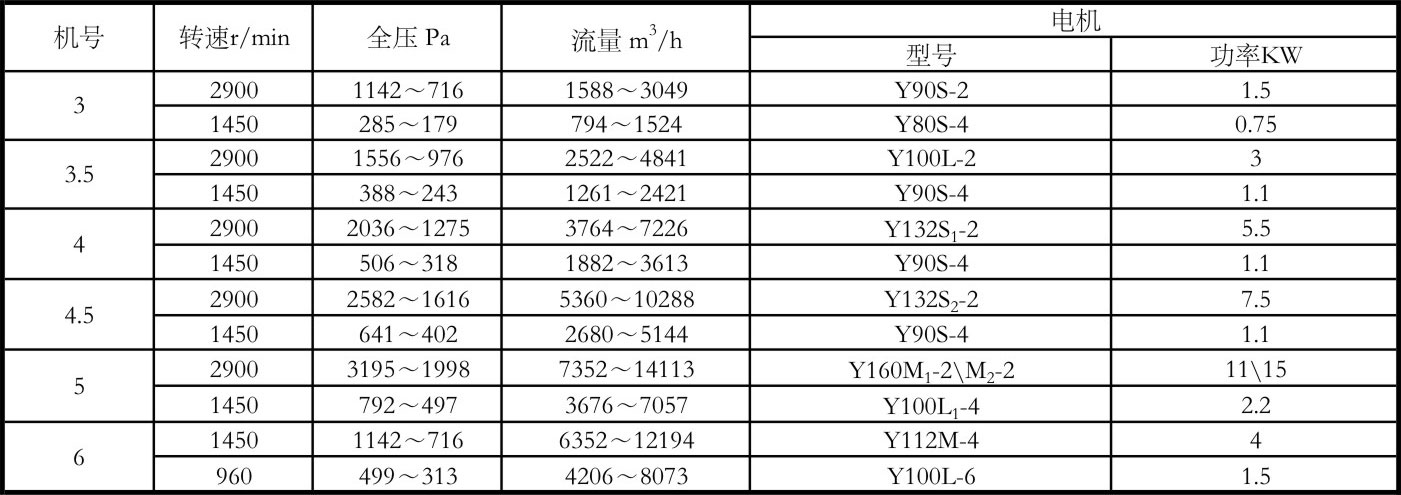

8-09 high pressure centrifugal fan performance parameters table

1, Uses: 8-09,9-12 type of iron furnace dedicated high-pressure centrifugal fan, suitable for 1 L / h, 2L / h, 3L / h, 7L / h melting rate of iron furnace blast performance requirements. The fan can also be used as a variety of furnace forging furnace furnace blast, but also for conveying air and non-corrosive, non-spontaneous combustion, does not contain viscous material gas. The temperature of the input medium does not exceed 80 ℃, the media contains dust and hard fine particles not more than 150mg / m3.

2, the form: 8-09 fan for a single inhalation, machine number has No.6.8A, 7.1D, 8D, 8.5D, 9D a total of five.

9-12 fan for a single inhalation, machine number No6.8A, 7.1 A, 7.7A, 8D, 9D a total of five machine number.

8-09,9-12 fan can be made clockwise or counterclockwise rotation in two forms. From the motor side of the face, such as the impeller clockwise rotation, said clockwise rotation of the fan to "Shun" said, according to counterclockwise rotation, said counterclockwise rotation fan to "inverse" said.

The outlet position of the fan is expressed as the angle of the outlet of the enclosure. The "Shun" and "reverse" fans can be made into 0 °, 90 ° and 180 ° angles.

3, structural features: 8-09,9-12 fan by the impeller, chassis, air inlet, rotation group, seals, base and other components, for the 8-09 machine with local assembly mechanism, the other machine using the overall body The

① Impeller leaves are designed according to the new efficient forward fan theory. Impeller after forming by static, dynamic balance correction, so smooth and reliable operation.

② the chassis with ordinary steel welded into a scroll shell as a whole.

③ the air inlet made of convergent streamline of the overall structure, with bolts and front cover group fixed.

④ rotating group by the spindle, bearing box, coupling and other components, the spindle made of high quality steel. For the 8-09 type No.71 D, No. 8D using rolling bearing lubrication grease lubrication, for the 8-D9 type No. 5.8, using rolling bearing lubricating oil lubrication.

8-09 high pressure centrifugal fan performance parameters table