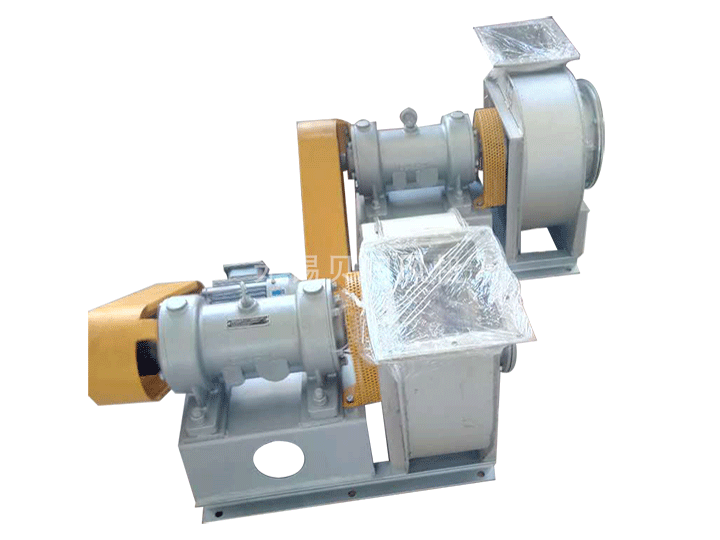

W5-48 centrifugal fan

W5-48 series of high-temperature fan for non-corrosive, non-spontaneous combustion, the maximum temperature does not exceed 700 ℃ high temperature gas, which dust should be less than 150mg / m³.

W5-48 series of high-temperature fan type

1, the fan made a single inhalation, the machine number No4,5,6.3,8,10,12.5 a total of six machine number.

2, from the motor side of the face, the impeller clockwise rotation called the right cyclone, with "right"; the other side of the left fan, with "left" said.

3, the fan outlet position to the chassis of the outlet angle that "left" and "right" can be made 0 °, 45 °, 90 °, 135 °, 180 °, 225 ° six angles.

W5-48 series of high-temperature fan structure

At present, more industrial boilers series, the quality of coal with poor quality, with the resistance of different dust, the fan required air volume, wind pressure difference. In order to meet the above situation, taking into account the fan economy, the use of V-belt (C-type) drive, so not only to a machine with a different speed to meet the same tonnage boiler configuration of various types of dust collector requirements, reducing the fan series and machine Number, but also easy to use the unit according to the actual situation, choose a different speed to get the required air volume and wind pressure.

The fan is mainly composed of impeller, chassis, air inlet, regulating door and transmission group and other components.

Impeller - 12 sheets from the rear tilting plate blades, welded to the middle of the curved wheel cover and flat disc. Static and dynamic balance test correction and speeding operation experiment, so the operation is smooth and reliable, high strength.

Enclosure - welded with steel plate into a swivel. No8 above "left", "right" to pass. In the spiral plate also opened a cleaning door, easy to remove the accumulation of leaves and the shell of the fouling, to ensure that the impeller balance and aerodynamic performance.

Inlet - made into a convergent streamline overall structure, bolted to the fan inlet side.

Adjust the door for the petal-shaped, No4 ~ 6.3 for the 9, No8 above 11, the axial installation in the air inlet, due to the use of external transmission structure, flexible and convenient transmission. Adjust the range from 0 ° (full open) to 90 ° (fully closed) to adjust the door to move the position: from the direction of the inlet to see the right side of the right whirlwind, moving from the bottom up by the whole closed to the whole Open the direction of the left whirlwind fan, move from the top down is the whole closed to fully open direction. In order to adjust the doors of the normal work, must be very good lubrication. Grease with molybdenum disulfide high temperature (260 ℃) grease, the fan can still ensure high temperature operation lubrication.

Transmission group - by the spindle, bearing box, pulley and other components. Spindle is made of high quality steel, the fan are used rolling bearings, water cooling the overall bearing box, therefore, must be installed water pipes, water consumption varies with the environment, generally 0.5 ~ 1m3 / h considerations. Bearing box with thermometer and oil level indicator, lubricating oil with 30 # oil, oil pressure by the oil level signs.

W5-48 series of high-temperature fan type

1, the fan made a single inhalation, the machine number No4,5,6.3,8,10,12.5 a total of six machine number.

2, from the motor side of the face, the impeller clockwise rotation called the right cyclone, with "right"; the other side of the left fan, with "left" said.

3, the fan outlet position to the chassis of the outlet angle that "left" and "right" can be made 0 °, 45 °, 90 °, 135 °, 180 °, 225 ° six angles.

W5-48 series of high-temperature fan structure

At present, more industrial boilers series, the quality of coal with poor quality, with the resistance of different dust, the fan required air volume, wind pressure difference. In order to meet the above situation, taking into account the fan economy, the use of V-belt (C-type) drive, so not only to a machine with a different speed to meet the same tonnage boiler configuration of various types of dust collector requirements, reducing the fan series and machine Number, but also easy to use the unit according to the actual situation, choose a different speed to get the required air volume and wind pressure.

The fan is mainly composed of impeller, chassis, air inlet, regulating door and transmission group and other components.

Impeller - 12 sheets from the rear tilting plate blades, welded to the middle of the curved wheel cover and flat disc. Static and dynamic balance test correction and speeding operation experiment, so the operation is smooth and reliable, high strength.

Enclosure - welded with steel plate into a swivel. No8 above "left", "right" to pass. In the spiral plate also opened a cleaning door, easy to remove the accumulation of leaves and the shell of the fouling, to ensure that the impeller balance and aerodynamic performance.

Inlet - made into a convergent streamline overall structure, bolted to the fan inlet side.

Adjust the door for the petal-shaped, No4 ~ 6.3 for the 9, No8 above 11, the axial installation in the air inlet, due to the use of external transmission structure, flexible and convenient transmission. Adjust the range from 0 ° (full open) to 90 ° (fully closed) to adjust the door to move the position: from the direction of the inlet to see the right side of the right whirlwind, moving from the bottom up by the whole closed to the whole Open the direction of the left whirlwind fan, move from the top down is the whole closed to fully open direction. In order to adjust the doors of the normal work, must be very good lubrication. Grease with molybdenum disulfide high temperature (260 ℃) grease, the fan can still ensure high temperature operation lubrication.

Transmission group - by the spindle, bearing box, pulley and other components. Spindle is made of high quality steel, the fan are used rolling bearings, water cooling the overall bearing box, therefore, must be installed water pipes, water consumption varies with the environment, generally 0.5 ~ 1m3 / h considerations. Bearing box with thermometer and oil level indicator, lubricating oil with 30 # oil, oil pressure by the oil level signs.